Material can be analyzed in solution or it can be analyzed as a solid by laser ablation.

Solids

In contrast to some other analytical methods (e.g., SIMS), no special sample preparation or storage is required. For example, thin sections can be examined in the lab with an optical microscope and then transferred directly into the laser cell, with in situ analysis underway in minutes.

How to Prepare Samples

- 1" epoxy rounds should be ~1 cm thick and have a parallel, well-polished underside so that light from underneath can transmit through the epoxy.

- Standard uncovered thin sections of any thickness, should be no more than 27 mm wide and polished; if yours (e.g., European) are wider, grind them down.

- Carbon or gold coating should be removed from epoxy mounts and thin sections prior to analysis. This can be done by hard scrubbing with kimwipe + methanol, or by gentle polishing using 1/4 um diamond paste/spray. Check with a reflected microscope that all carbon/gold has been removed.

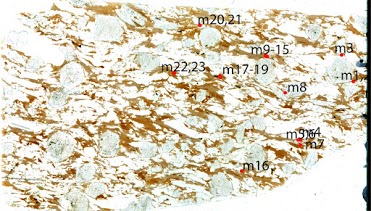

- The locations of all grains should be marked on an electronic image of the mount or thin section that is 1-4X the size of a page. Each grain in thin section should have a second location image that is zoomed in to show just the grain of interest and the immediately surrounding grains; this is absolutely necessary for monazite because it looks very 'ordinary' in reflected light, but generally not necessary for zircon, titanite, and rutile because of their distinct reflected-light signature.

- Zircon grains should be imaged with CL; for planning purposes, a typical spot size is 20-40 microns.

- Monzite, xenotime, and allanite grains should be imaged with x-rays; good choices include Y, Ca, Sr, La, Nd, Th, or U; for planning purposes, a typical spot size is 7-10 microns.

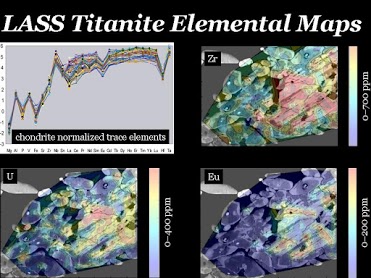

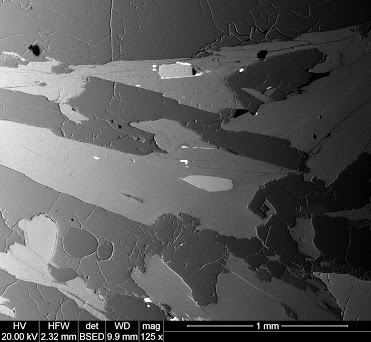

- Titanite and rutile grains should be imaged with BSE and/or x-rays (e.g., Zr, Al, Th, U); for planning purposes, a typical spot size is 30-40 microns.

- Because of poor laser absorption, calcite and apatite sections need to be polished and a minimum of 50 microns or thicker.

How to Prepare Thin Sections For Analysis

Download a guide specific to in-situ monazite sample preparation

- Image the thin section and mark the grains of interest

- Image each individual grain of interest with BSE or another imaging technique. Always place the grain of interest in the center of the image. For monazite and zircon, you MUST create a zoomed-out image (see below):

and a second, zoomed-in image (again, below).

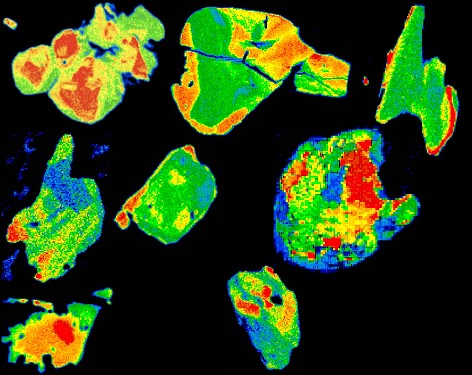

- Image each individual grain with either BSE (titanite, rutile), CL (zircon), or x-rays (monazite, xenotime, allanite). Below is an example set of an x-ray images for monazite:

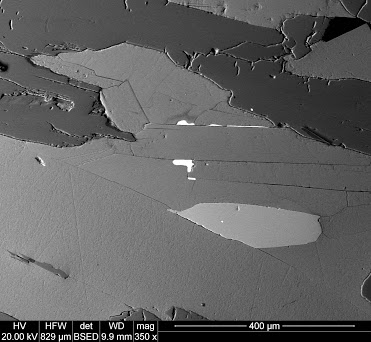

Below is an example BSE image of a titanite:

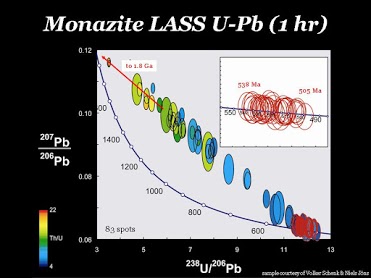

Example Analyses

Free Pilot Data

If you need some pilot or proof-of-concept data for a proposal, contact us about acquiring some. Reasonable requests will not be refused.

We are also happy to provide support letters for proposals that specify analytical techniques, costs, etc.